Products and Solutions

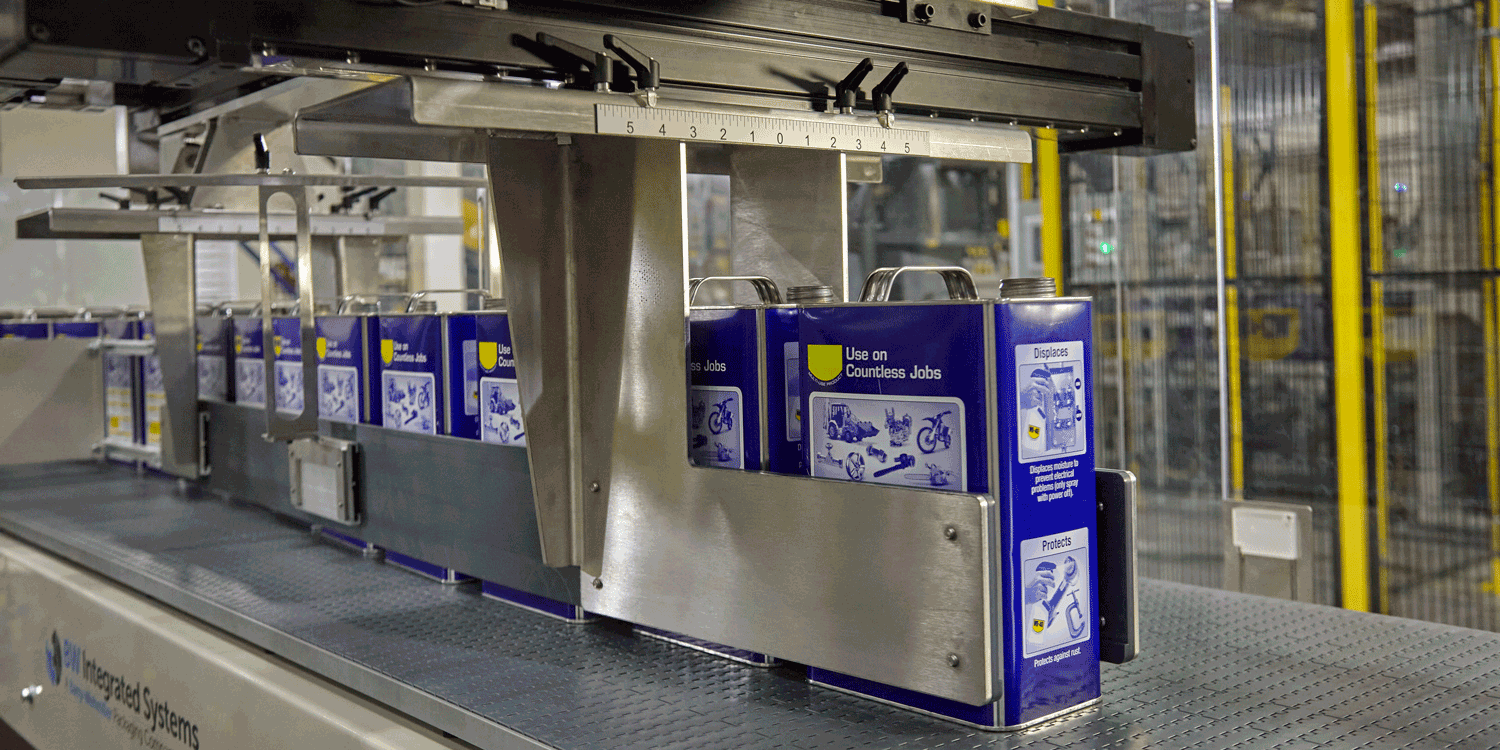

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

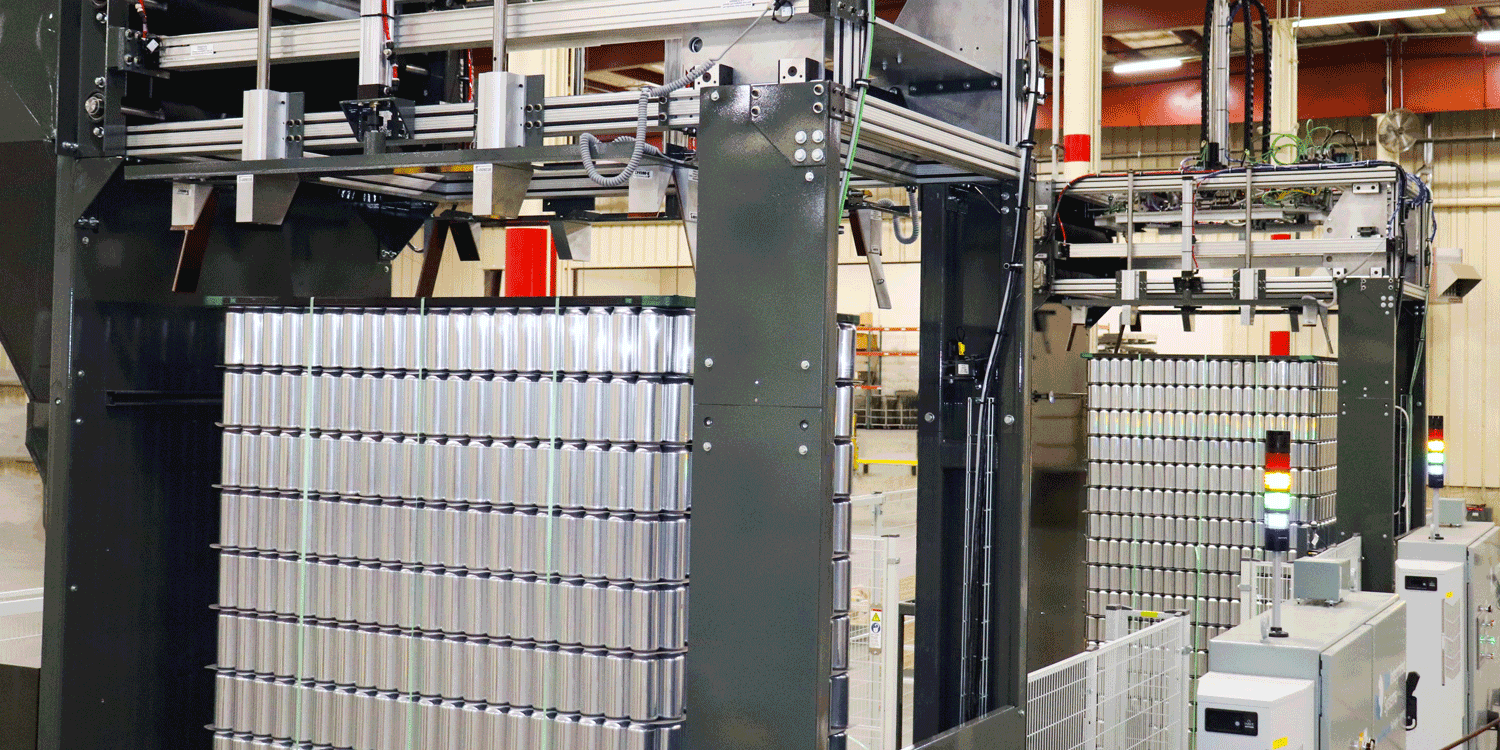

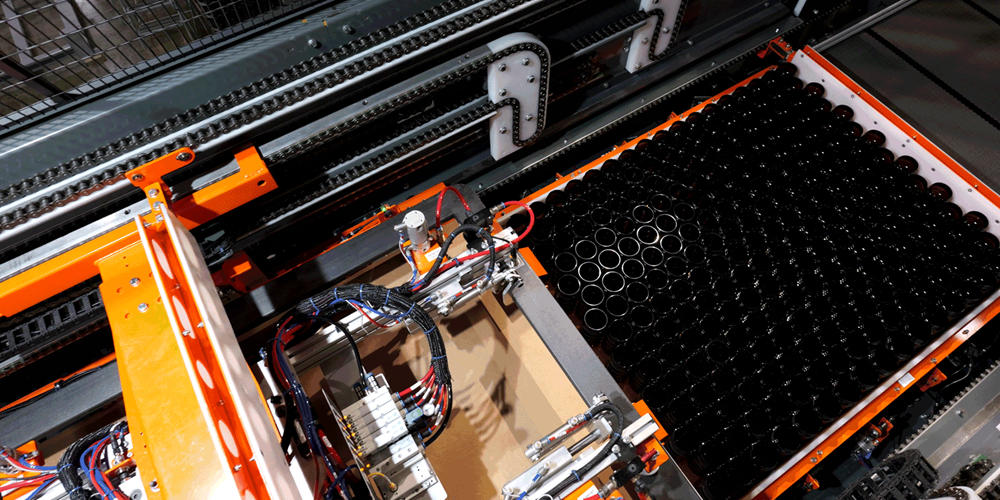

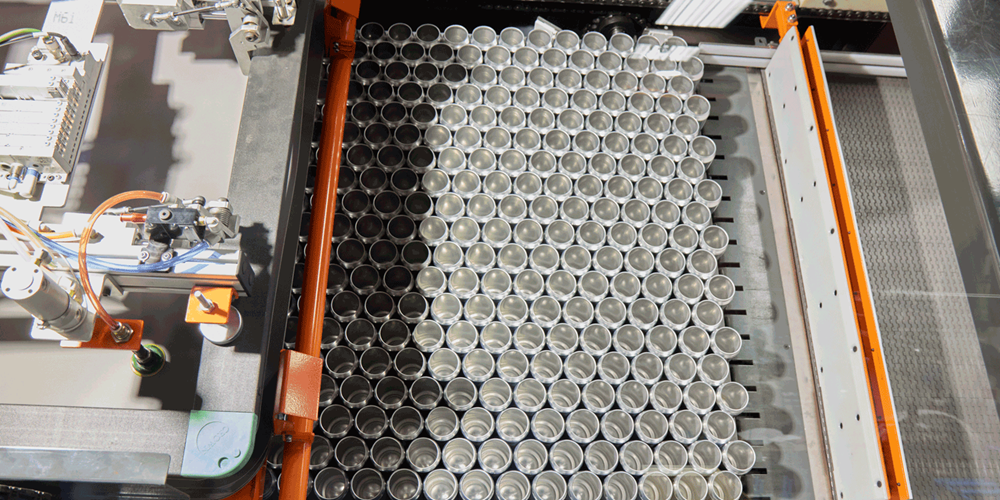

Goldco Fortis 3000 Bulk Depalletizer

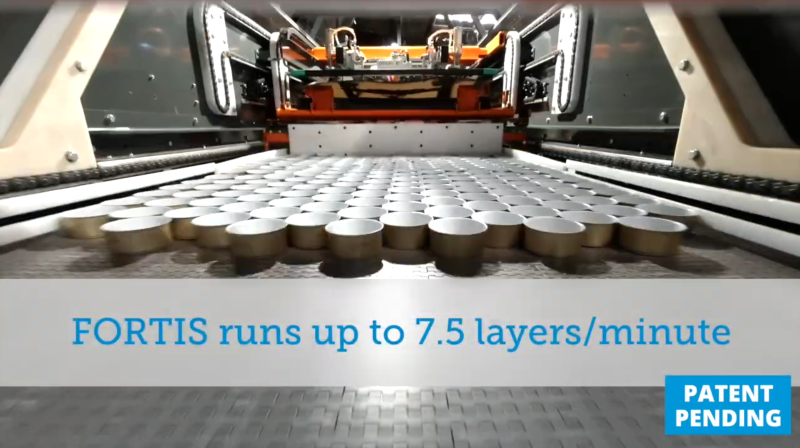

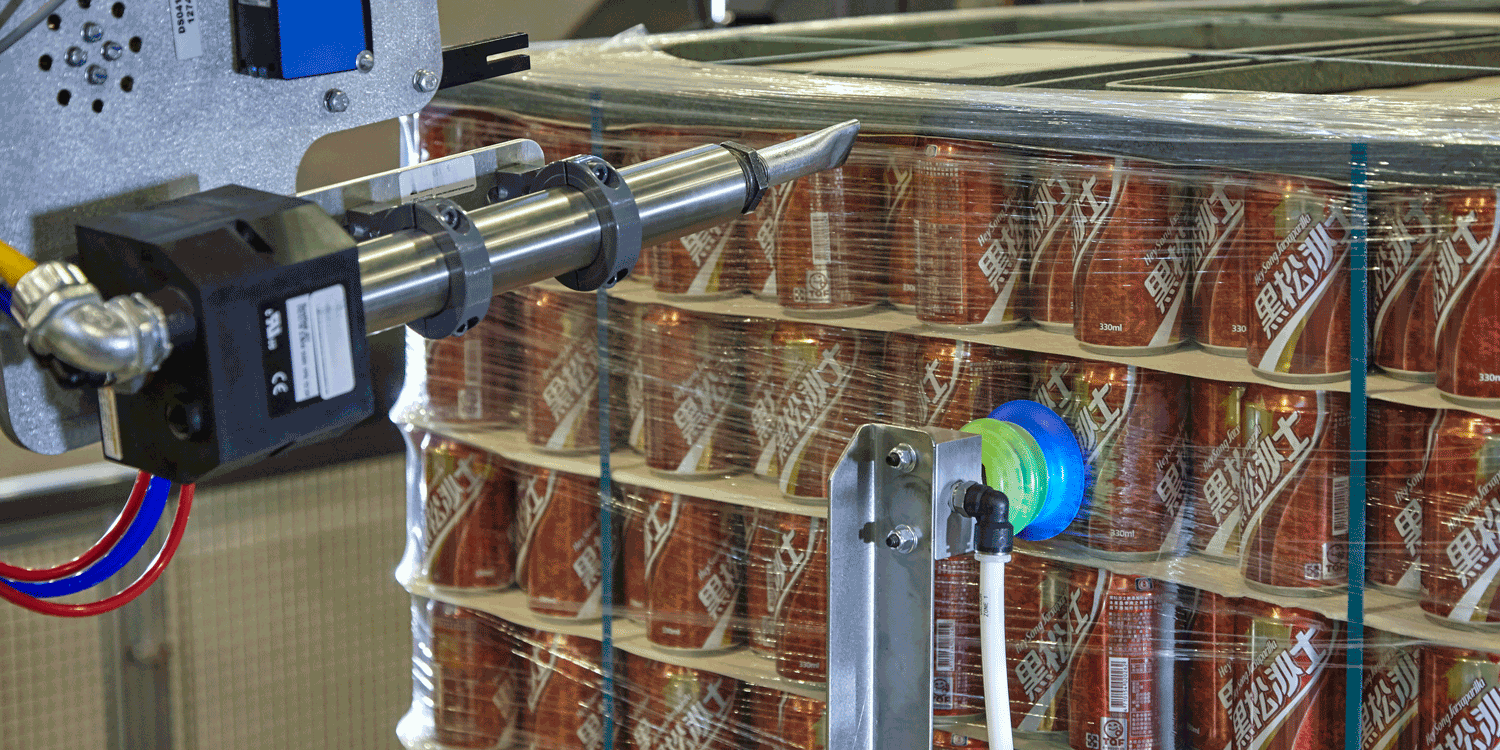

Goldco Fortis 3000 High-Level Bulk Depalletizers - the ultimate solution for effortlessly removing empty containers from pallets and seamlessly feeding them into production lines. Experience the power of Fortis as it deploys its cutting-edge technique for handling dunnage, efficiently bringing the consolidated dunnage down to floor level for effortless robotic separation. Our robotic dunnage handling system is designed to meet supplier needs by separating layer pads, top frames, and pallets. With its unrivaled capabilities, Fortis thrives in a 24-hour/day production environment, effortlessly handling empty steel, aluminum, and PET containers.

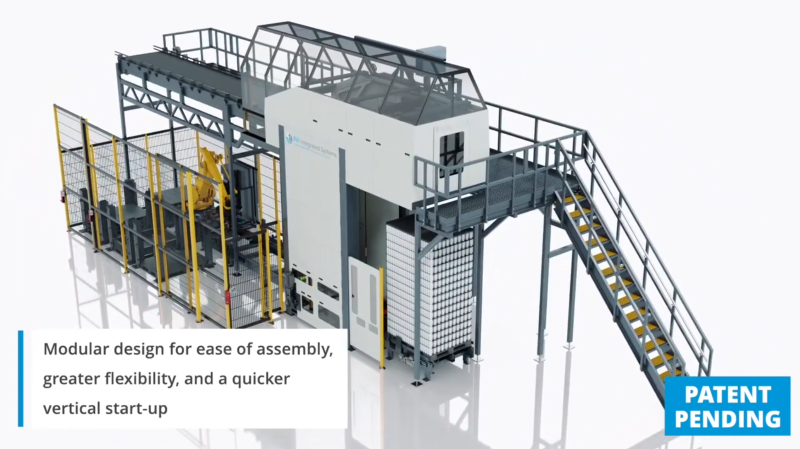

Goldco’s Bulk Depalletizers are configurable to meet the specific requirements of any plant. By optimizing client efficiencies, reducing labor demands, and accommodating line speeds, this advanced system is designed using modular assemblies that facilitate easy shipment and rapid installation.

Effortless Dunnage Handling

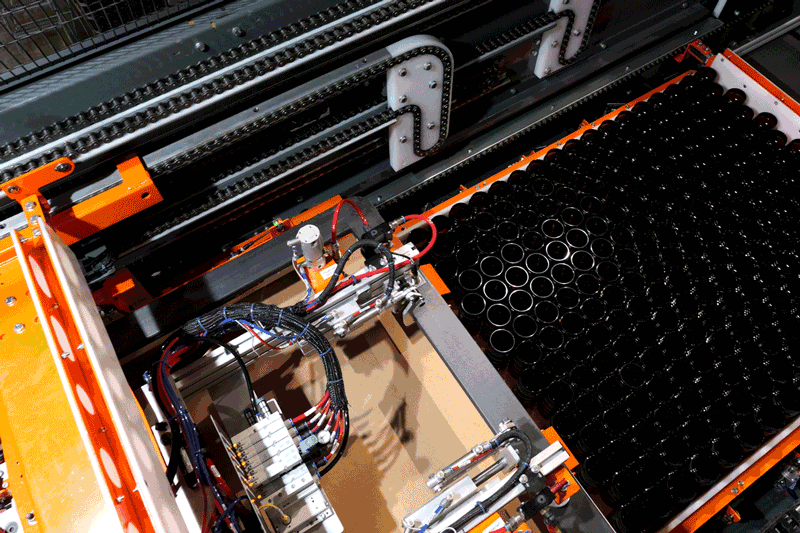

Fortis depalletizers utilize high-speed servo-driven sweep bars, working seamlessly together to ensure gentle handling and secure containment during the sweeping operation. To efficiently remove dunnage materials, the dunnage pick head effortlessly removes the top frame and layer pads between each sweep, storing them in the sheet tray until all containers have been fully unloaded from the pallet. The stack of layer pads and the top frame are carefully placed onto the empty pallet and sent to floor level.

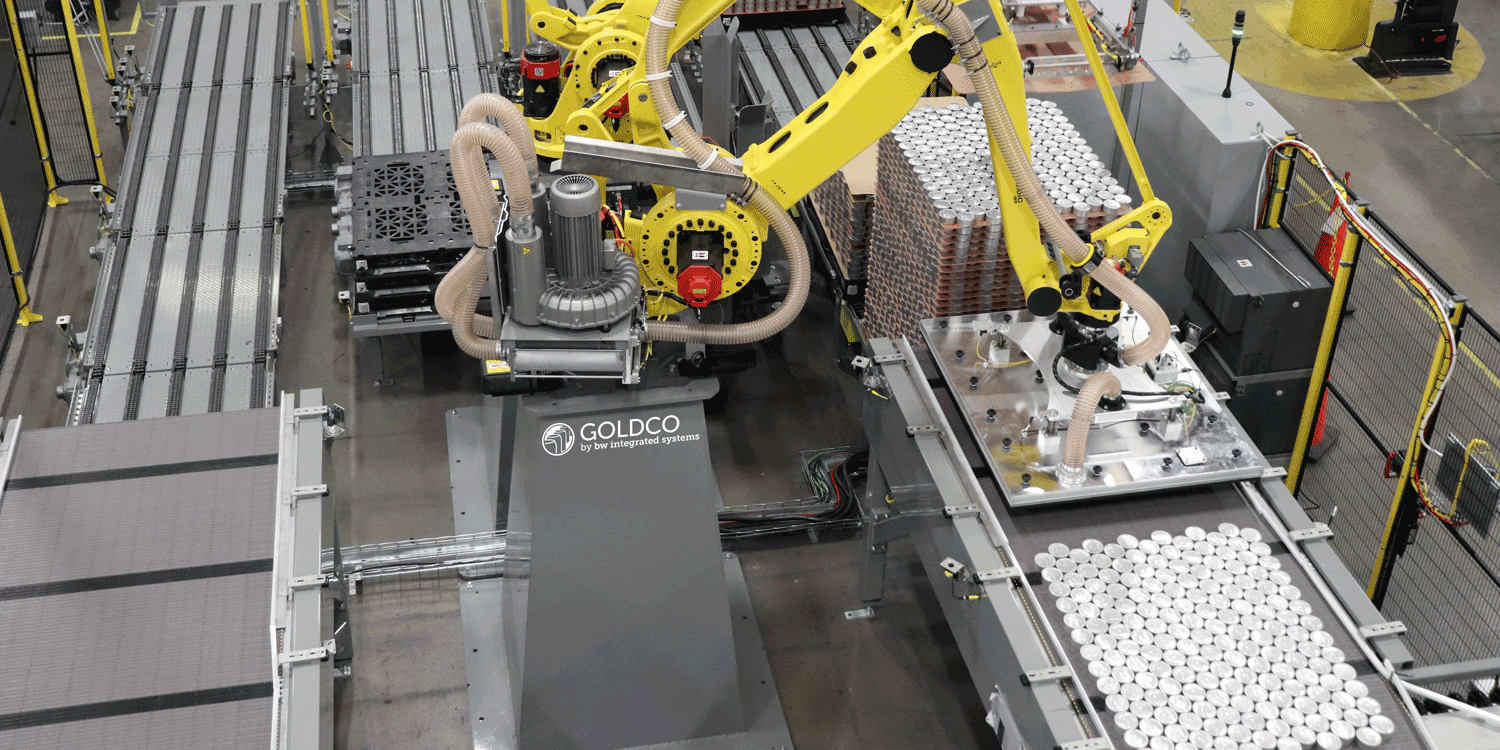

The layer pads, top frames, and pallet are then conveyed out of the hoist to our unique robotic dunnage handling system. This system expertly separates the dunnage materials into separate stacks for easy floor-level removal. The configuration of the dunnage area can be tailored to meet the specific needs of each client.

Comprehensive Solutions with Integrated Systems

For a streamlined operational experience, our depalletizing solutions can be integrated with optional pallet accumulation conveyance systems and our efficient pallet Destrapper. Choose Goldco Fortis 3000 for a complete, high-performance solution that enhances productivity and simplifies your workflow.

Discover how Goldco Fortis 3000 High-Level Bulk Depalletizers can transform your production line today!

Key Features

- Robust 4-chain servo-driven hoist

- Enhanced performance with dual servo-driven sweep bars

- Servo-driven sheet tray for seamless operation

- Convenience of all electric/pneumatic operation

- Servo-driven primary dunnage pick head with vacuum cups for layer pad handling and grippers for top frames

- Multiple layer pad grippers for increased flexibility

- Robotic dunnage handling system with separate hoppers for layer pads, top frames, and pallets

Technical Data

Available Options

- Automatic sheet leveler for transition to accumulator

- Recipe-driven servo positioning for layer pad grippers

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

1305 Lakeview Dr

Romeoville IL 60446

US -

+1 (630) 759-6800 -

+1 (800) 527-0494 (Customer Service) -

+1 (800) 527-0494 (Field Service)

-

1320 Wards Ferry Rd

Lynchburg VA 24502

US -

+1 (434) 582-1200 -

+1 (888) 553-0095 (Customer Service) -

+1 (888) 553-0095 (Field Service)

Jump to...

Jump to...