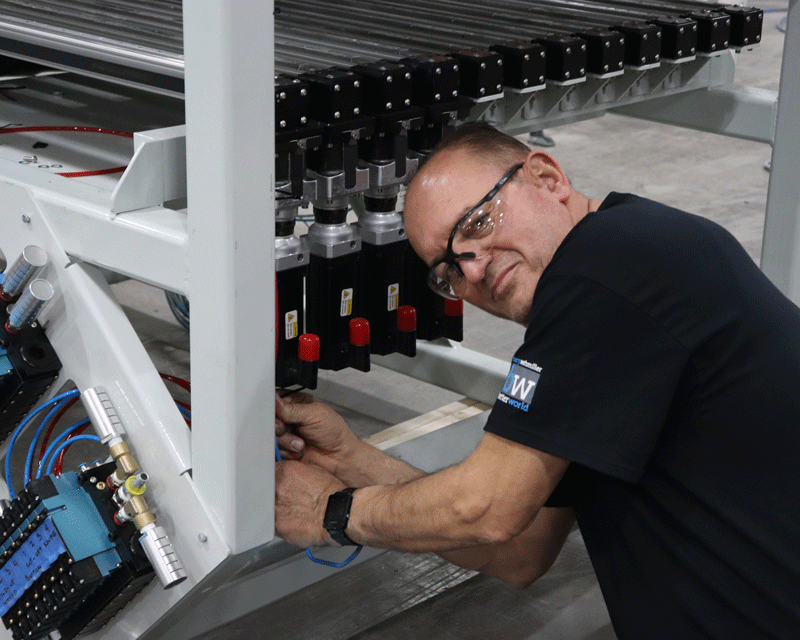

Upgrades & Rebuilds

Is your packaging equipment showing signs of wear or struggling to keep up with today’s production demands? At BW Integrated Systems, we help you get more from your existing machinery. Whether you're looking to improve efficiency, meet new safety standards, or adapt to changing product requirements, our upgrades and rebuilds extend the life and performance of your equipment without the cost of full replacement. Need help evaluating your upgrade options? Contact our upgrades team today!

REQUEST AN UPGRADE OR REBUILD LEARN MORE

Legendary Equipment Meets Modern Performance

Our experienced engineering and aftermarket teams specialize in modernizing legacy equipment across our full portfolio of trusted brands. From mechanical rebuilds to control system upgrades, we help you stay competitive with solutions tailored to your production goals. We offer upgrades and rebuilds for the following brands:

- Ambec container handling, conveyance, rinsing, and controls solutions.

- Fleetwood can end handling and conveying solutions.

- Goldco palletizing, depalletizing and material handling solutions.

- Harland and previously branded Accraply pressure-sensitive and self-adhesive labeling solutions.

- Nigrelli cartoning, multipacking, shrink bundling, tray and case packing solutions.

- Sleevit shrink sleeve application and labeling solutions.

- Stact case palletizing and specialty palletizing solutions.

- Stanford converting solutions for shrink sleeves and flexible packaging.

- SWF case and tray forming, erecting and sealing solutions.

- Trine roll-fed label application solutions.

Specific Services & Offerings

Whether you're looking to modernize controls, improve safety, or adapt to new product formats, our upgrade and rebuild services are designed to help you get more from the equipment you already trust. Our offerings include:

- Equipment Audits & Feasibility Assessments

We evaluate your current equipment to determine the most cost-effective upgrade or rebuild options based on your production needs. - Mechanical Rebuilds

Restore your equipment from the ground up with updated components, improved safety features, and enhanced performance—without the cost of new machinery. - Control System Upgrades

Replace outdated hardware and software with modern automation and servo technology to improve speed, fault recovery, and user interface. - Changeover Optimization

Reduce downtime and increase flexibility with engineered conversion kits that streamline changeovers and enable new product configurations. - Safety Enhancements

Bring your equipment up to today’s safety standards with mechanical and electronic upgrades that improve operator safety and ergonomics. - Product Conversion Kits

Adapt your existing machines to run new product sizes, formats, or group patterns—maximizing your investment and production flexibility. - Efficiency Improvements

Target specific performance gaps—like speed, maintenance interruptions, or changeover delays—with proven modifications that boost throughput. - Certified Pre-Owned Equipment

Looking for a cost-effective solution? We offer certified pre-owned Tray and Bliss Formers, rebuilt to meet current performance and safety standards.

Request an Upgrade or Rebuild

Ready to modernize your packaging equipment? Complete the upgrade and rebuild request form below. Our team typically responds within 48 hours.