Products and Solutions

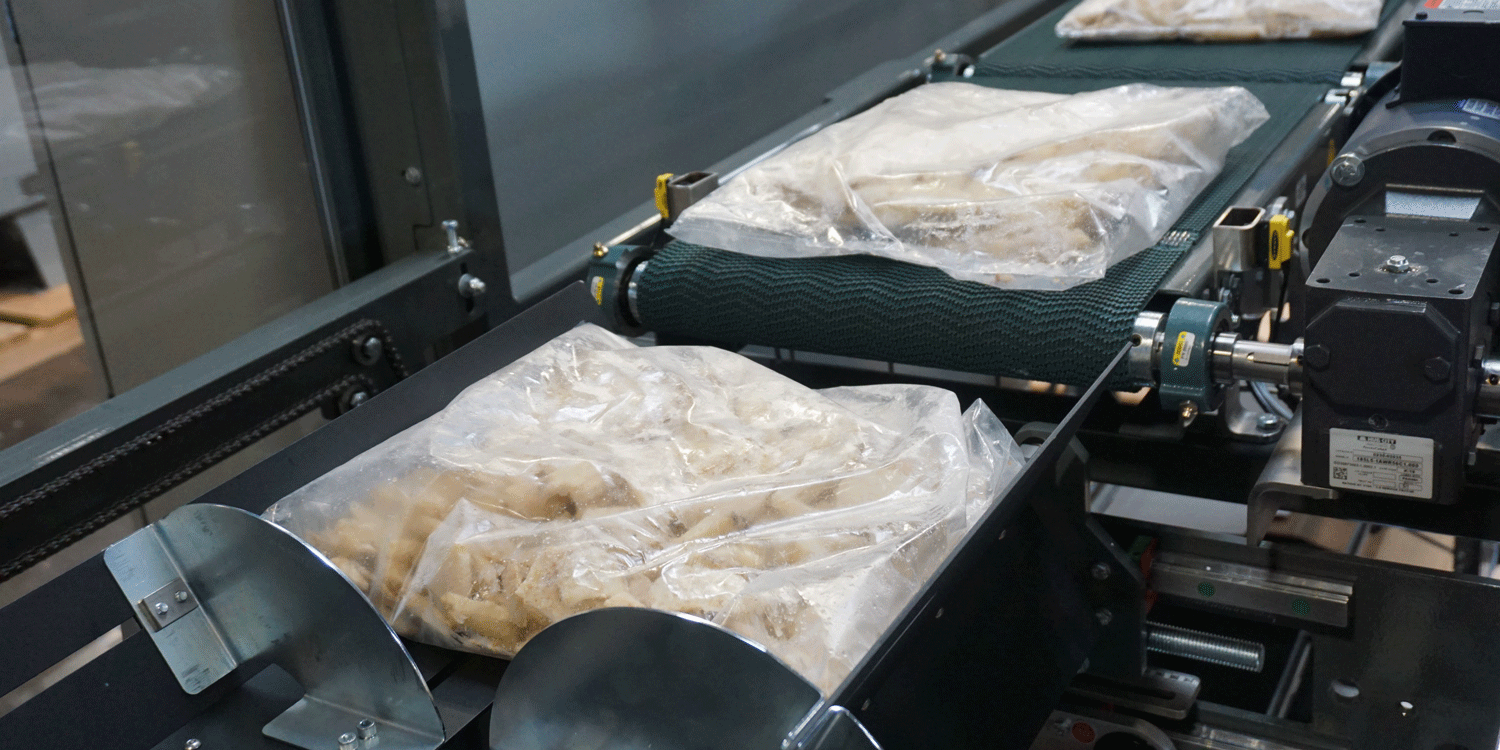

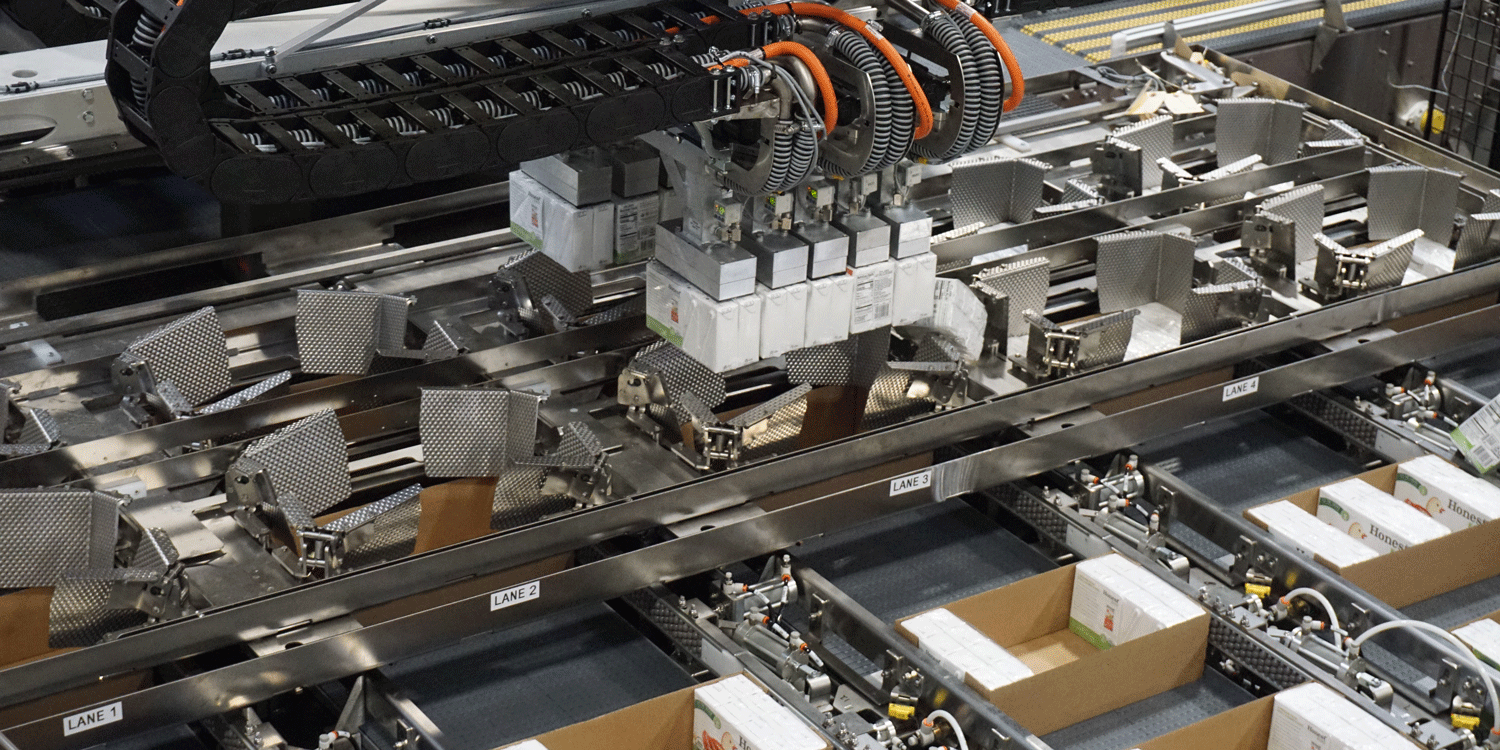

Every production line tells a different story. Yours might be scaling up, adapting to new formats, or simply looking for more consistency. Wherever you are in that journey, we’re here to help you make the most of it. BW Packaging’s product portfolio is comprised of reliable labeling, container handling, and end-of-line packaging technologies built on decades of engineering excellence and a truly human culture that puts people first. From conveying and cartoning to palletizing and controls, our solutions are designed to integrate seamlessly into your operation.

Are you looking for a solution that’s backed by a team that’s committed to supporting you for the long haul? Explore our solutions below to take the first step!

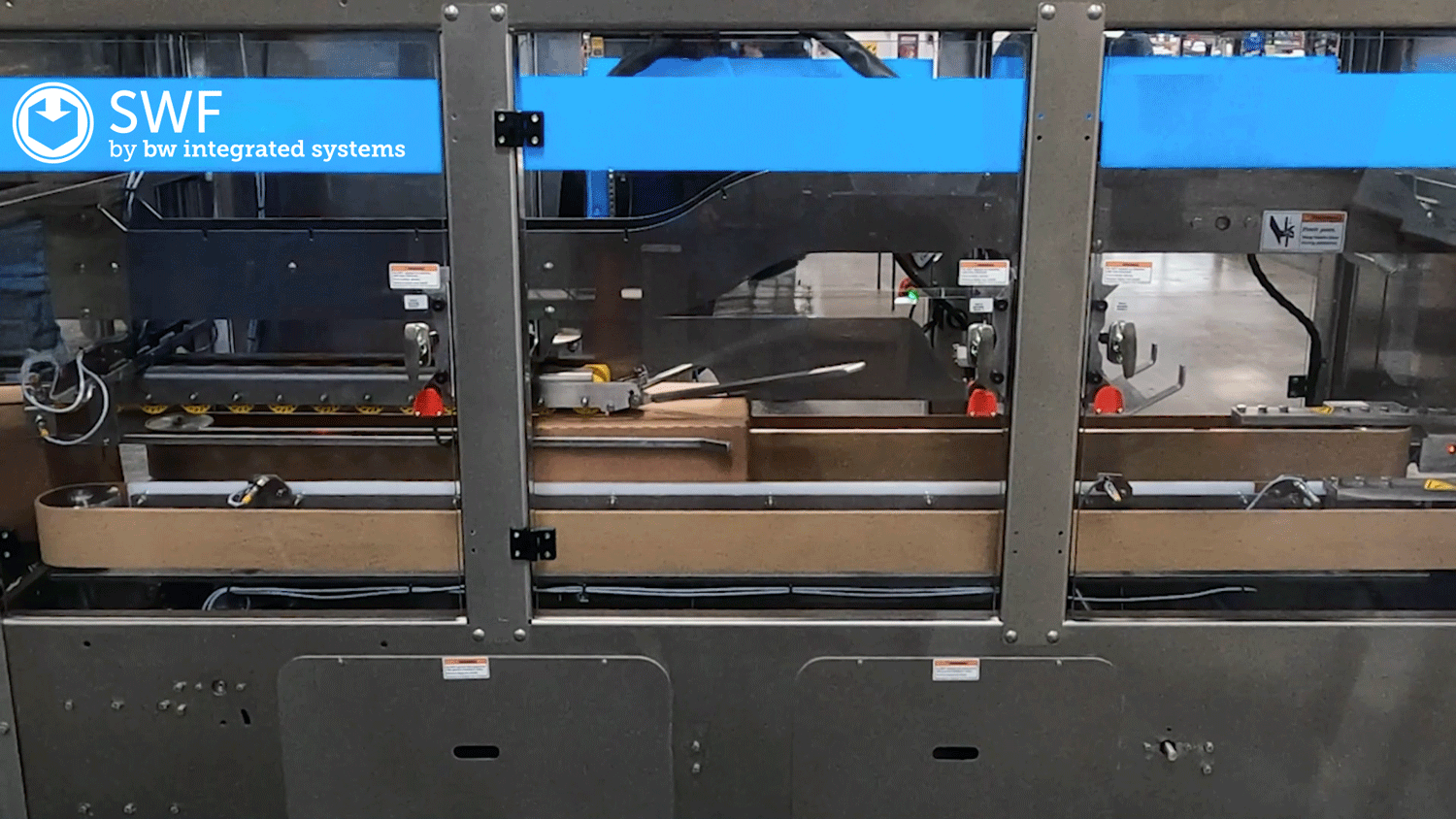

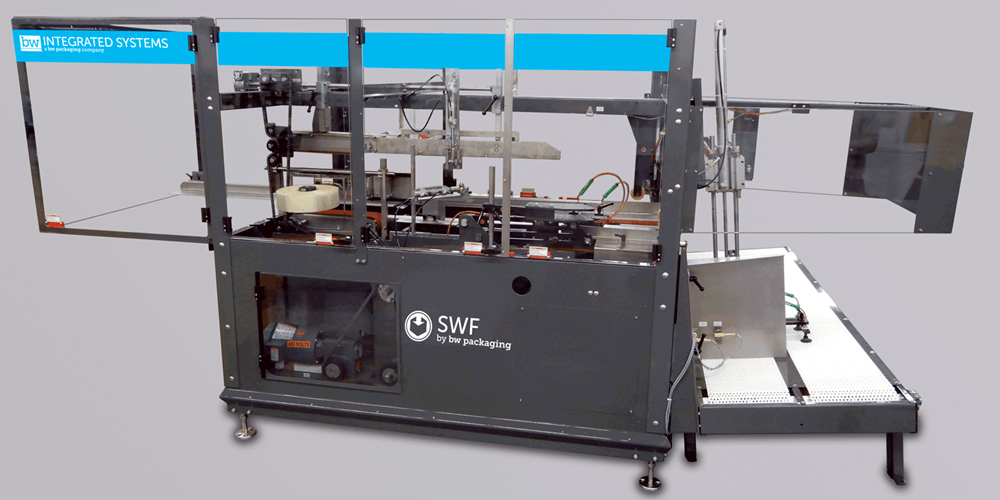

SWF CE 420T / CE 425G Case Erectors

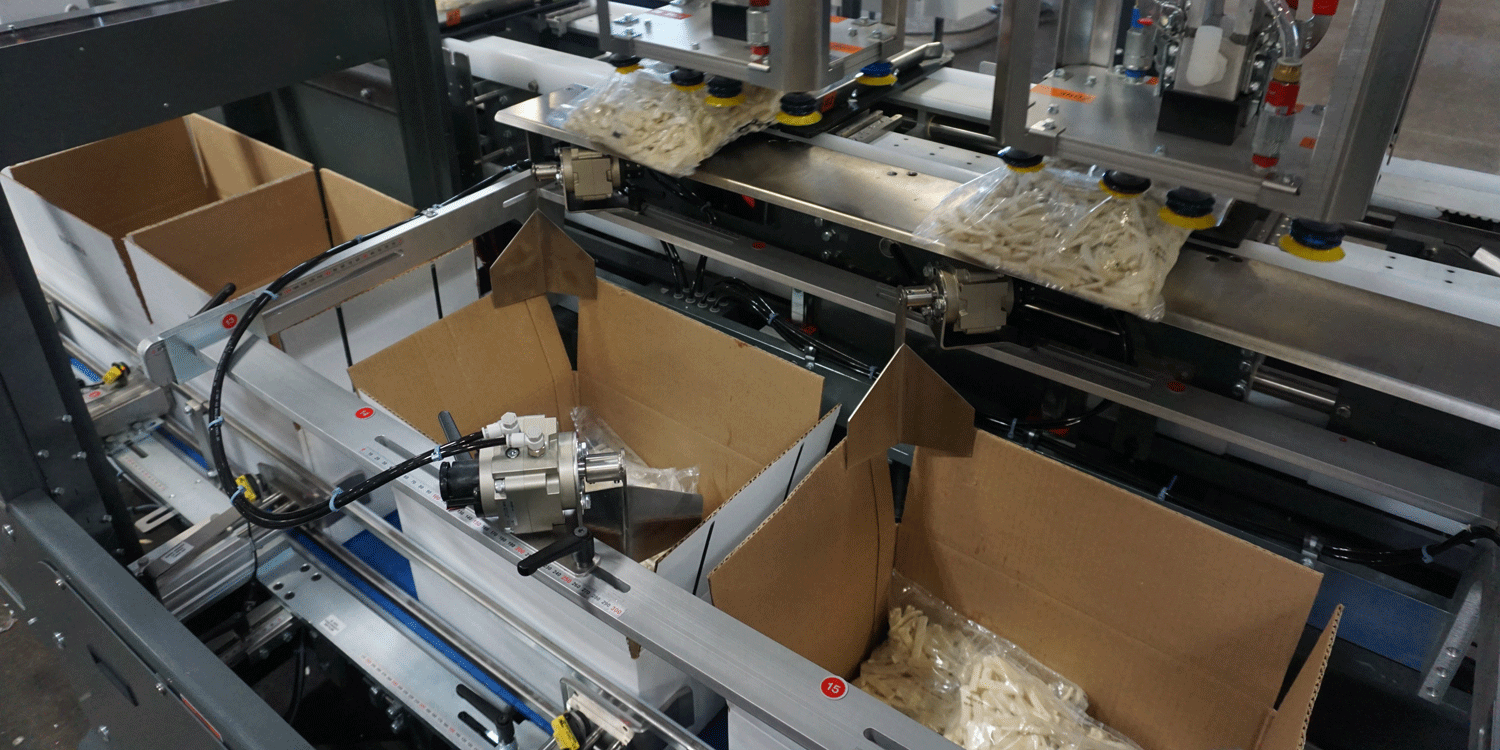

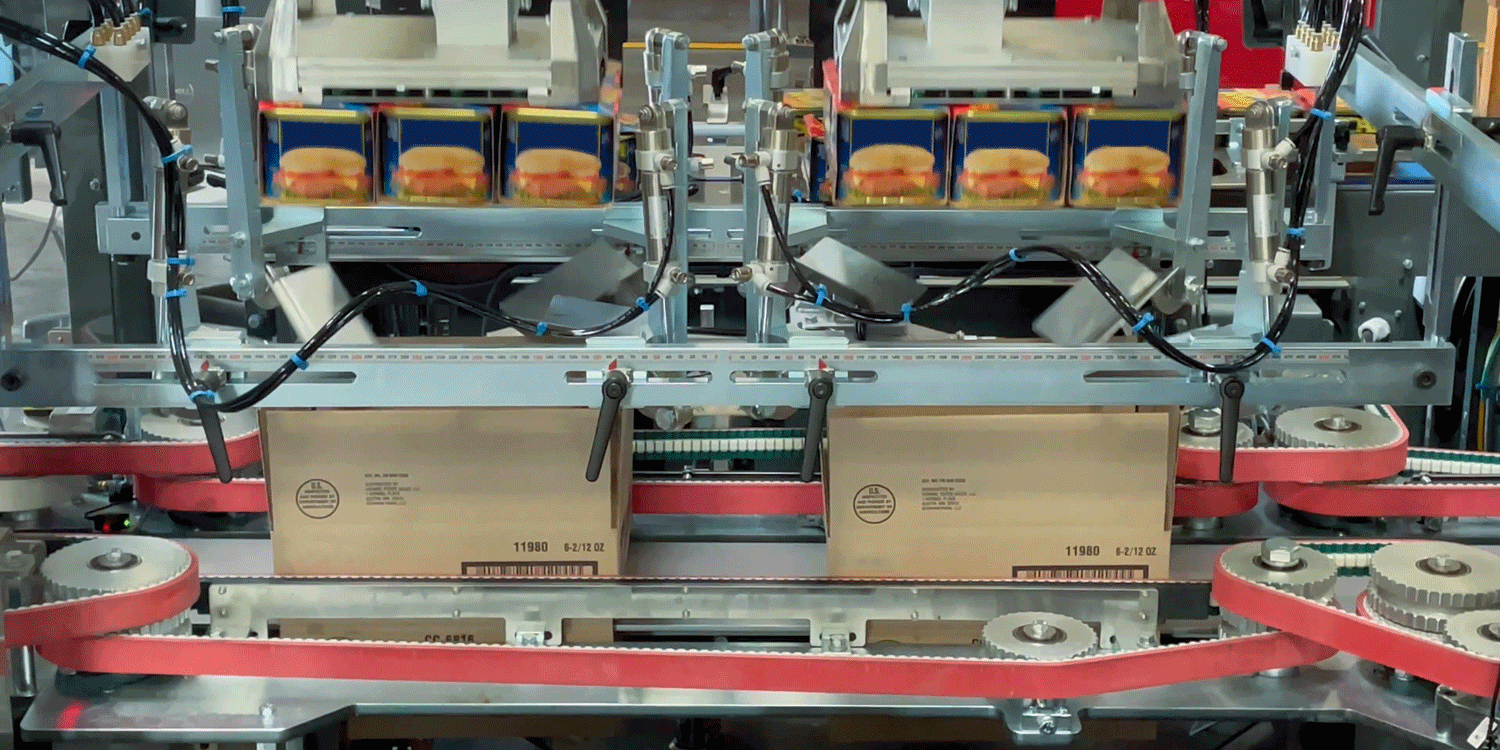

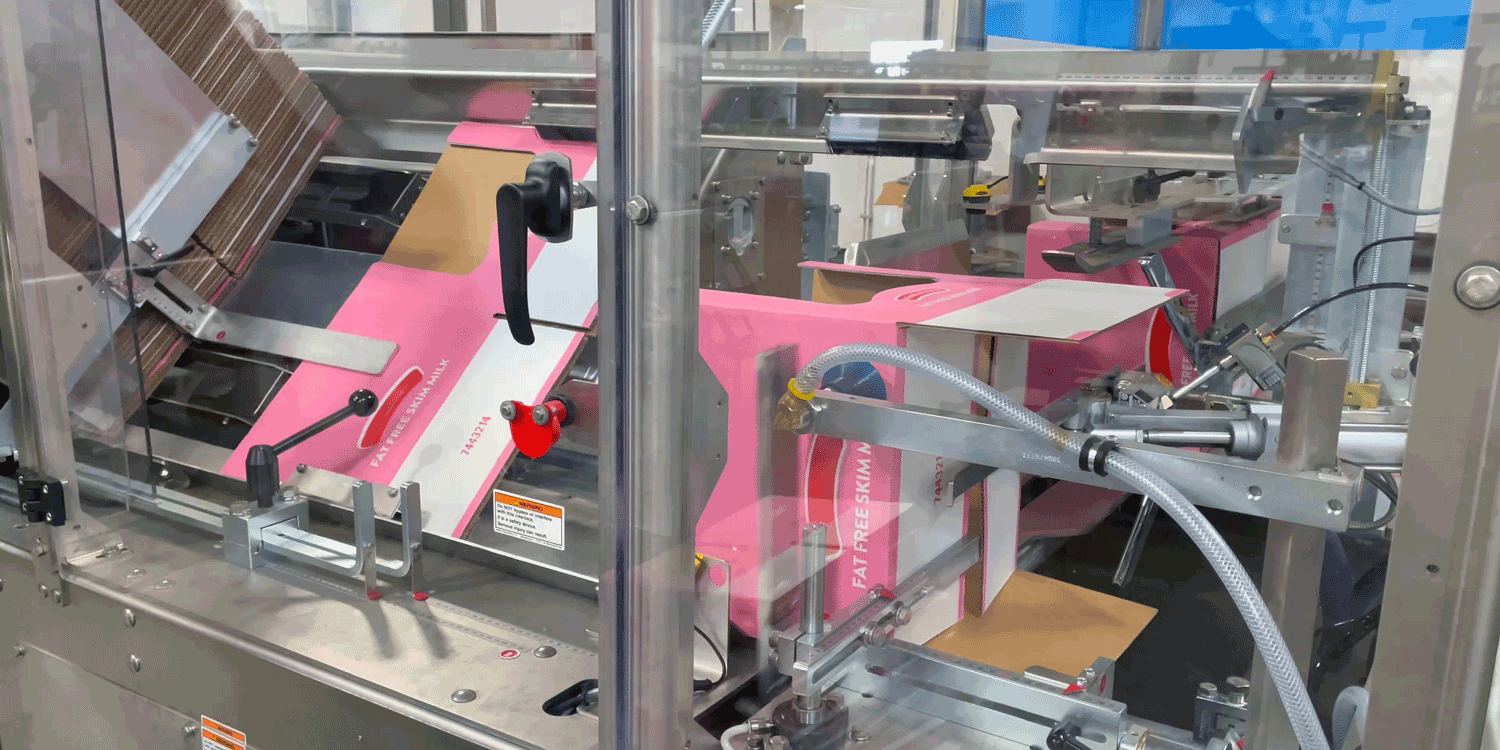

The SWF CE Series of Case Erectors, include the highly efficient CE 420T and CE 425G models. These state-of-the-art machines are designed to effortlessly select, erect, square, and seal the bottom flaps of regular-slotted (RSC) and half-slotted (HSC) corrugated cases, streamlining your packaging process.

CE 420T and CE 425G Models: Unmatched Performance

The CE 420T operates with an impressive sealing mechanism using tape, achieving speeds of up to 20 cases per minute. In contrast, the CE 425G model enhances efficiency by applying a predetermined glue pattern for even faster operation, reaching speeds of up to 25 cases per minute. Please note that actual speeds may vary based on model configuration and case size.

Innovative 6-Foot Right-Angle Magazine

Both models come equipped with an advanced 6-foot right-angle magazine, with an optional powered magazine available to facilitate a seamless transition between stacks of cases. This feature ensures uninterrupted operation, no matter the case variations, as our intelligent case selection system handles warped boards and other irregularities smoothly.

User-Friendly Operation with Advanced Technology

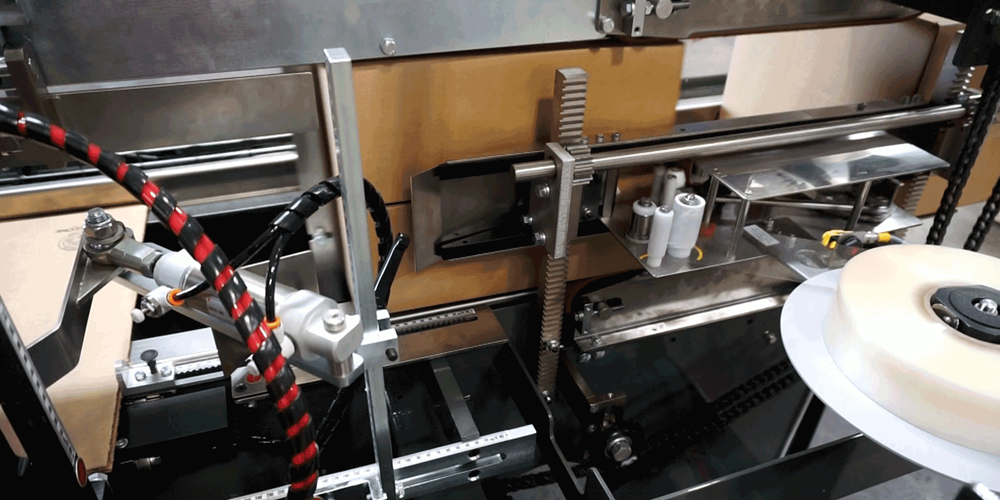

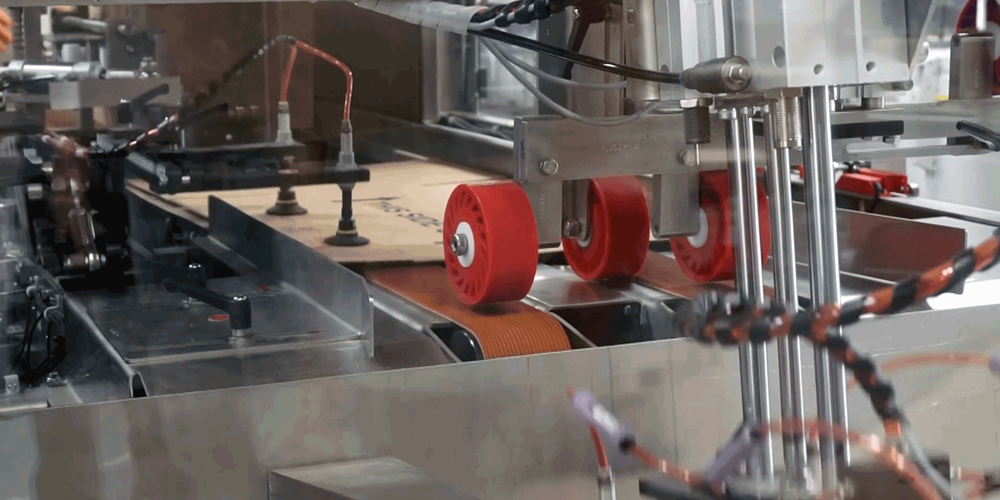

Operating the CE Series Case Erectors is simple and efficient. Start by loading a stack of cases into the magazine, and our vacuum cups will do the rest. They efficiently select a case from the top of the stack and transport it to the erecting station, where an advanced vacuum cup system opens and erects the case. The minor flaps at the front and rear fold inward at a 90-degree angle, followed by the major flaps.

Once erected, a mechanical walking beam transfers the case onto top- and bottom-driven feed belts, guiding it through the taping head of the CE 420T. Here, our precision tape application system securely applies tape to the leading panel, positioning it approximately 2 inches (51mm) from the bottom. To ensure optimal adhesion, a series of rollers and a brush meticulously “buff” the tape, while rear pressure rollers compress the trailing end for a perfectly sealed case. For those using the CE 425G, hot-melt adhesive is applied to the minor flaps before the case proceeds to compression and squaring.

Elevate Your Packaging Efficiency Today!

With SWF CE Series Case Erectors, you can optimize your packaging line for speed, reliability, and efficiency. Experience the advantages of advanced technology in case erecting and sealing. Contact us today to learn more about the CE 420T and CE 425G models and how they can transform your packaging operations!

Key Features

- Opposing vacuum cups in the erecting station

- Changeover in under 3 minutes

- Maintenance free vacuum generators

- Case flaps are pre-folded in a stationary position

- Allen-Bradley PLC

- Seals with polyester, PVC and polypropylene tapes (CE 420T)

- Nordson hot-melt glue system (CE 425G)

Technical Data

Available Options

- Powered magazine

- Magazine extensions

Packaging Styles

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

1949 E Manning Ave

Reedley CA 93654

US -

+1 (559) 638-8484 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

-

810 Industrial Park Blvd

Fergus Falls MN 56537

US -

+1 (218) 739-3321 -

+1 (800) 344-8951 (Customer Service) -

+1 (559) 638-8739 (Field Service)

Jump to...

Jump to...