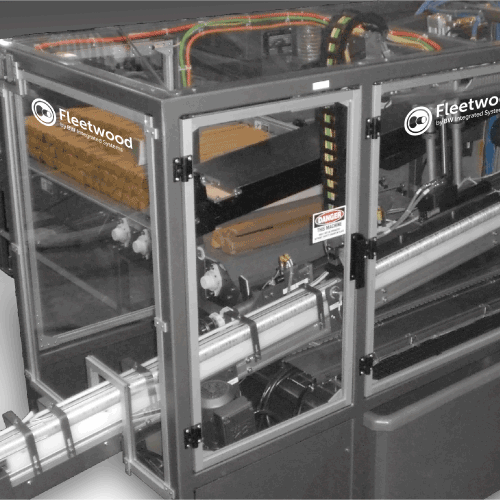

Fleetwood’s ALF 130 Automatic Lid Feeders eliminates the manual unloading and feeding of bagged lids, freeing up resources to maximise can filling operations. The ALF 130 is loaded with bags of lids and automatically removes each paper bag, then feeds the lids to the filling line.

Bagged sleeves of can lids are manually loaded onto the ALF’s feed table to allow for continuous production with only periodic operator interaction. The feed table automatically indexes on-demand and supplies individual sleeves to the ALF. One by one, sleeves are automatically fed and oriented to an optimum cutting position. In a smooth continuous motion, each bag is cleanly slit along the full length of the bag without touching the lids. The bags are completely removed, and gravity dropped into a scrap bin under the machine.

All Fleetwood equipment is designed around the same customer-focused, reliable, and innovative approach that has made us a leader in the can end market since 1956.

Key Advantages:

- Small footprint

- Easy loading and delivering product on demand

- Low maintenance requirements

- Reliable 24/7 operation

- Automatic reversed end detection and ejection system

- Designed for easy operator and maintenance access

- Change parts available for product size changes

- User-friendly Allen-Bradley PLC controls

Options:

- Custom conveyor solutions and layouts

- Stainless-steel construction

- Slinky packages for priming and purging lids from trackwork

- Various bag feed table capacities

- Product size change parts

- Siemens PLC control system

Contact our experienced sales teams today for a comprehensive review of your application(s) and to see how our Fleetwood ALF 130 Automatic Lid Feeders can benefit your company.