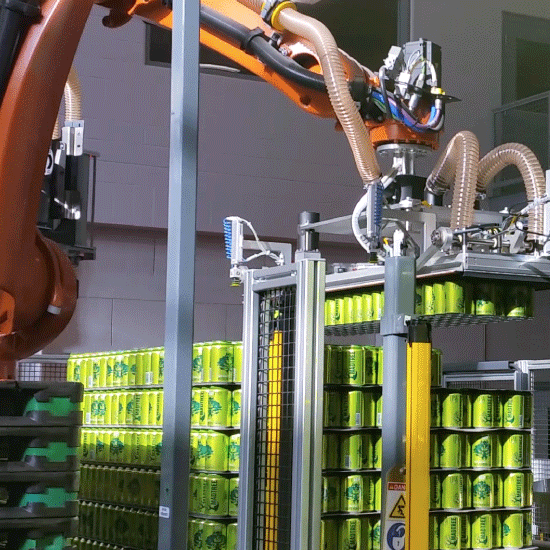

BW Integrated Systems’ Robotic Bulk Depalletisers are designed to depalletise multiple product sizes from numerous incoming prodct lines and delivery them to many distribution lines. Depending on the end-of-arm tooling used, the Depalletiser can depalletise empty or filled cans (aluminium or steel), plastic containers, or cases.

Robotic Bulk Depalletising Machine Operation

After a new load arrives, an ultrasonic sensor in the robot’s end-of-arm tooling senses the load’s position. This sensor is used to determine the precise position of each layer, beginning with a full load. Once the load’s position is determined, the robot removes the top layer pad and top frame (if applicable) and places both onto a dunnage stack. The robot continues depalletising the load until the last layer has been removed. Once the load has been depalletised, the robot places the empty pallet onto a dunnage stack. As pallets are stacked, the robot uses proximity sensors to sense when the empty pallet has been placed in the dunnage stack. These sensors prevent pallet damage caused by the over-travel of the robot. The pallet may optionally be stacked with a conventional pallet magazine.

Key Advantages:

- Flexible footprint design

- Accurate package placement

- Gentle product handling

- Highly adaptable to product changes

- Handles various product sizes simultaneously

- Using a single depalletizer, other traditional designs are not capable of handling multiple product lines without extensive changeover

- Eliminates the need for multiple conventional depalletizers, due to its high-flexibility

- Multiple dunnage handling options

- State-of-the-industry safety and monitoring systems package

- Lower maintenance when compared to a conventional depalletizer

Contact our experienced sales teams today for a comprehensive review of your application(s) and to see how our Robotic Bulk Depalletisers can benefit your company.